James Tyrrell, editor of nanotechweb.org

JPK Instruments is one of

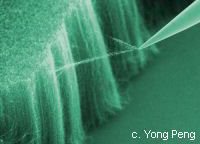

Torsten Jähnke, chief technology officer of JPK and one of the company's founders, knows the firm's products inside out. He spoke to nanotechweb.org about what it takes to develop an SPM for biological applications.

"It is important to introduce new technology into biology as a turnkey solution," Jähnke said. "Operators do not necessarily have a background in instrumentation, which you may find in physics or engineering."

Sample handling is another factor to consider. "The workflow can be completely different to other fields," explained Jähnke. "Biologists often take the same sample, mostly in liquid, from one tool to the next to build up a complete profile of the structure." Against this backdrop, the SPM has evolved to fit in with the whole analysis process.

"You must create a tool that can be combined with other tools – today's BioSPMs are increasingly integrated with other techniques, such as Raman spectroscopy and fluorescence microscopy," said Jähnke. "Users want to measure the chemical properties of their sample and to combine the data with SPM and optical images at the same spot and at the same time."

For a company like JPK this means partnering with leading research labs and attending not just SPM events but a wide range of related workshops in other disciplines, like fluorescence and confocal microscopy. In-house, the firm has put together a multi-skilled team to develop its instruments. "I think part of our success is due to the fact that at JPK, biologists sit in the same room as the engineers," commented Jähnke.

SPMs have come a long way since their inception. Closed-loop scanning stages have all but eliminated the problems related to piezo creep and hysteresis, but one of the biggest developments in recent years has been in the software.

"The user interface has improved tremendously," said Jähnke. "Researchers can calibrate or auto-align the system with one click." Software is now responsible for controlling the temperature and humidity of the sample and it plays a major role in guiding the user through the instrument.

"Operators don't want a six month learning period when they switch to a new instrument," explained Jähnke. "Today, technicians can get to grips with the equipment very quickly and that is due to the software."

No comments:

Post a Comment