Finland and China team up in nanotechnology

NanoChina

Finland's national nanotech initiative (FinNano) is rapidly advancing on the international scene. After kickstarting cooperation with Russia last week, FinNano is now sowing seeds in China.

Finland is a leading partner in the Europan Union's nanotech group NMT, and directs the EU's material technology group MATERA.

The partners in Finland–China NAMI cooperation aim to create world class research and put Sino–F innish nanotech products on the market together by 2010.

The Chinese Minister of Science and Technology (MOST) Dr. Wan Gang and Vice Minister Dr. Shang Yong joined in the celebration of the opening of China International Nanotech Innovation Cluster (CINIC) in Suzhou on Saturday. Finland has set foot in Suzhou, signing agreements for nanotechnology development and commercialisation.

Mr. Juho Rissanen, the Beijing representative of Tekes and counsellor of science and technology at the Embassy of Finland, gave an opening speech in Chinese informing the new MOST Minister on the current status of Finland-China nanotech cooperation. Dr. Markku Lämsä, who leads Finland's nanotech programme, signed a cooperation agreement with Suzhou nanotech cluster. Represented by Mr. Jaani Heinonen of Tekes Shanghai office and the Consulate General of Finland, the Finnish Technical Research Centre VTT also signed a cooperation agreement with Suzhou.

"The willingness to team up and the amount of joint projects proposed clearly show the demand for deeper collaboration between China and Finland in the area of nanotechnology. The Sino–Finnish NAMI Nanotech Program can also positively increase the exchange of know-how between the European Union and China", says Dr. Lämsä.

The China–Finland NAMI (Nanotechnology Strategic Mutual Cooperation Initiative) was signed in Beijing in January 2007, and more than 30 project proposals and expressions of interest have been collected so far. The first cooperation projects under the NAMI programme have been launched in October.

Finland is the first country to sign a national level strategic cooperation agreement with China on nanotechnology. The new Finnish technology programme on functional materials, with a budget of 200 million euros, was introduced to the Chinese Ministry of Science and Technology last Monday in Beijing. It is expected that still more cooperation projects will be generated under this new programme, to be implemented under the NAMI framework. Both the national nanotech programme and functional materials programme are funded and directed by Tekes, and coordinated by Spinverse Inc., a private Finnish technology consultancy.

Ambitious objectives for cooperation

Finland–China NAMI cooperation aims at increasing the competitiveness of industrial sectors in the two countries. The industries include information and communication technologies, pulp and paper, chemicals, metals and other materials, diagnostics and healthcare. The production of energy using new technologies such as solar cell and fuel cells may also be considered.

In Finland, nanotechnology is one of the focus areas of national innovation policy, with extensive public and private investments. The Finnish Nanoscience and Nanotechnology Programme FinNano is a coordinated action on a national level to increase the expertise in science and technology. Finnish public funding organisations are investing more than 120 million euros in nanoscience and nanotechnology programmes between 2005 and 2010.

Launch of Joint BMBF "Nanoanalysis" Project for Chip Development

From Nanoforum

DRESDEN, OBERKOCHEN/Germany, 06.11.2007.

The companies AMD, Carl Zeiss SMT and Qimonda are launching a cooperation within the framework of the joint “Nanoanalysis“ project which is funded by the German Federal Ministry of Education and Research (BMBF) with a sum of 12 million euros. The partners are working together on new analytical and characterization methods required for the development of the next chip generation. This strengthens the competency of the Dresden microelectronics site, particularly in the fields of semiconductor analysis and metrology.

As announced today by Dr. Wolf-Dieter Lukas, Head of the BMBF Department “Key Technologies – Research for Innovations“, the strategic setup and expansion of microelectronics competency centers is an important goal of the BMBF IKT2020 program. “Only by setting targeted priorities in research funding will we succeed in maintaining Dresden’s leading role in high-tech chip production and in further expanding it through such innovative approaches as here in the field of nanoanalysis.“

The newly founded “Carl Zeiss Innovation Center Dresden“ is an important module within the joint “Nanoanalysis“ project. Here, ultrahigh resolution particle beam systems are being installed which use electron and ion beams instead of light. These systems enable the imaging, analysis and processing of specimens down to the level of individual atoms. In this way, they are playing a decisive role in the characterization of three-dimensional semiconductor structures and in the development of new materials for chip fabrication. “With its Innovation Center, Carl Zeiss SMT is becoming involved in ‘Silicon Saxony’, Europe’s leading microelectronics cluster. Not only is the cluster being strengthened in its function as a research location, but the ongoing development of the local semiconductor industry is also being promoted”, explains Dr. Dirk Stenkamp, Member of the Carl Zeiss SMT Board of Management.

“As a manufacturer of innovative microprocessors, we are faced with the challenge of producing increasingly complex structures with smaller and smaller dimensions and with maximum yield“, says Dr. Udo Nothelfer, Vice President AMD Fab 36. “Therefore, process control at an atomic level plays a key role. Through our joint work in the Carl Zeiss Innovation Center Dresden, we have access to leading edge electron and ion microscopes and believe we can therefore further accelerate the introduction of new technologies. The experience gained in industrial utilization may be incorporated at an early stage in the development of future analytical systems.“

“With the structure dimensions now achieved, current storage cells can only be seen under the electron microscope“, says Frank Prein,

Managing Director Qimonda Dresden and Senior Vice President Technology Qimonda. “Only through the consistent enhancement of the analytical and measuring methods will it be possible to master the future challenges posed by the development and production of state-of-the-art storage technologies. Through the diversified integration of research partners, Qimonda will use the excellence of the research location for its technology competency center in Dresden within the framework of the joint ‘Nanoanalysis’ project and expand and strengthen its scientific network.“

In addition to the cooperation partners AMD and Qimonda, the “Carl Zeiss Innovation Center Dresden“ is available to all interested firms and institutes in the Dresden area. In particular, all partners of “Silicon Saxony”, e.g. the Dresden Technical University or the Fraunhofer Center Nanoelectronic Technologies CNT, can resolve application problems in the field of nanotechnology.

Faster and more efficient thanks to "defects"

From Nanoforum

Smaller, faster, more efficient: BASF research scientists are helping to revolutionize the future world of telecommunications - with the aid of three-dimensional photonic crystals. In a three-year project, BASF is researching into the development of these crystals together with partners such as Hanover Laser Center, Thales Aerospace Division, Photon Design Ltd., the Technical University of Denmark and the Ecole Nationale Supérieure des Télécommunications de Bretagne. joint ‘Nanoanalysis’ project and expand and strengthen its scientific network.“

Monday 17 December 2007

Nanotech Week European News

Posted by

P. M. Earl

at

Monday, December 17, 2007

0

comments

![]()

From Nanowerk

Nanogate AG was named overall winner of this year’s STEP Award yesterday evening. The prestigious award was made in recognition of the Saarbrücken-based nanotechnology company’s innovation and growth. The presentation ceremony was a gala event held on the fiftieth floor of the Commerzbank Tower in Frankfurt. The award is worth €100,000.

Nanogate AG made the running to win the overall award from among many top-class international applicants. The STEP Award, made by the F.A.Z.-Institut, Infraserv Höchst and many well-known sponsors, goes to SME growth companies in innovative fields ranging from pharmaceuticals, chemicals, life science, biotechnolgy, nanotechnology and materials management to renewable energy. They must be committed to the “spirit to expand” and have great future potential. The award, which is worth €100,000, is intended to give outstanding companies a major boost to help them achieve further positive development. The €50,000 cash component will influence the company’s result positively in financial year 2007.

Nanogate AG, a listed company, convinced an independent jury of representatives of business and scientific research with its innovative products and high-growth development. In recent years Nanogate AG has developed into a leading international enabler in the field of chemical nanotechnology and remains on course for success. As a product enhancer and partner in innovation Nanogate offers its customers numerous services along the value chain: from development and production of innovative nanocomposites and material systems to strong support for innovation and product integration.

The award was presented and speeches were made by Roland Mohr, general manager of Infraserv Höchst, and Volker Sach, general manager of the F.A.Z.-Institut. Nanogate CEO Ralf Zastrau accepted it. It consists of €50,000 in cash and an extensive service package of equivalent value that will support the company in its forthcoming growth phase.

“We are very proud to have won the overall STEP Award prize this year,” Ralf Zastrau said. He was delighted that the jury had shown appreciation of his company’s profitable growth and sustainable development. “In our work we create on a daily basis product and application innovations that give our customers a clear competitive edge,” he said. “In recent years we have made Nanogate a powerful market participant and are now extending our international profile significantly. This award made in recognition of our commitment is an extra motivation and we are delighted with this

support in implementing our company’s next phase.”

See Press Release 3i, 2006

Posted by

P. M. Earl

at

Monday, December 17, 2007

0

comments

![]()

White Paper - VCs to Nanotech: Don't Call Us

From Cientifica

For a sector predicted to be a trillion dollar market, there is a decided lack of private equity investor interest. Despite a massive public investment program totalling over US$18 billion, venture capitalists in 2005 invested only 0.14% of their funds in nanotech related companies.

Please click here.

Posted by

P. M. Earl

at

Monday, December 17, 2007

0

comments

![]()

Nanotech Week World News in Brief

From Small Times

Oxford Instruments to equip new UK lab

December 13, 2007 -- Oxford Instruments has received an order for nine process tool systems worth more than £2.5m ($5m) to equip a new cleanroom facility at the University of Southampton in the UK, the company announced in a news release.

The new Mountbatten research complex will serve the School of Electronics and Computer Science and the Optoelectronics Research Centre. Completion of the new building is anticipated for summer 2008.

The nine systems will provide the university with capabilities in research and development of novel nanoelectronic, MEMS and photonic devices. The order includes both plasma etch and deposition tools, with two Plasmalab System100 ICP etch tools, two Plasmalab80Plus open-loading RIE tools and two PlasmalabSystem100 PECVD tools, plus a number of Oxford Instruments' newest products: a FlexAL plasma/thermal atomic layer deposition (ALD) tool, a Nanofab nanowire and nanotube growth tool, and a large-chamber Ionfab ion beam system.

Nanostellar, World Gold pan for success in automotive catalysts

December 11, 2007 -- World Gold Council (WGC), the organization responsible for driving global demand for gold, and Nanostellar Inc., a developer of emission control technologies, have formed a partnership to introduce gold into the auto catalyst market.

The WGC has invested in Nanostellar to facilitate the commercialization and marketing of gold based technology that could increase industrial demand for gold.

Recently proclaimed a 2008 Technology Pioneer by the World Economic Forum, Nanostellar has developed a new product, NS Gold, a catalyst formulation for use in the automotive industry that for the first time includes gold alongside traditional platinum and palladium metals.

Gold enables manufacturers of light and heavy-duty diesel engines to reduce noxious emissions by as much as 40 percent more than existing pure platinum catalysts, enabling significant savings for automotive manufacturers, according to the WGC.

Indian nanotech students report no real classes

December 6, 2007 -- More than a year after the fanfare-filled launch of the National Center for Nanoscience and Nanotechnology at the University of Madras in India, its first 11 students are still waiting to receive a nanotech education, according to a report in the Indian newspaper The Hindu.

"From July to mid-September, we didn't have any class at all," the paper quoted one student as saying. "We were sitting under the trees, we didn't even have a classroom."

Another student told the paper that the center, which had promised to attract Nobel laureates, had not hired any staff.

The center has "drafted" a few staff members from other departments, but none of them are familiar with nanotechnology and are trying to teach the students based on Internet downloads.

"Not one professor is an expert in the nanotech field," one student told the paper.

Saudi Arabia announces plans for nanotech institute

December 3, 2007 -- Saudi Arabia's King Abdullah has approved a proposal to create a nanotechnology institute, which will be named after him, at a facility in Riyadh.

The institute will serve as an advanced technology research center for King Saud University.

"The future of the country depends on its youth, which in turn depends on human resources development," said Prince Naif in announcing King Abdullah's initiative. "The scientific community must exert more effort to train and qualify the Saudi youth."

Australian nanotech institute, Dow announce alliance

November 30, 2007 -- The University of Queensland's Australian Institute for Bioengineering and Nanotechnology (AIBN) and The Dow Chemical Company have announced a research alliance that will focus on two key areas: biomimicry and developing new manufacturing systems using biofeedstocks.

"Escalating oil costs and concerns about carbon dioxide emissions make it imperative to develop new manufacturing processes based on renewable substrates rather than diminishing fossil fuels," Peter Gray, AIBN's director, said in a news release.

"Scientific advances in the biosciences, have enabled researchers to genetically reprogram bacteria to produce the chemical building blocks of the future.

Andrew Liveris, Dow's chairman and CEO, said going back to nature was a further step forward in Dow's sustainable chemistry initiative.

"This alliance will help Dow to find more resource efficient ways to deliver even better products to markets and is a marvelous example of how the human element can work with nature to drive strategic growth at a company like Dow."

AIBN has more than 300 researchers housed in a new building complemented by an extensive suite of facilities.

Survey reports perceptions of nanotech impact by public, scientists

November 26, 2007 -- The unknown human health and environmental impacts of nanotechnology are a bigger worry for scientists than for the public, according to a new report published November 25 in the journal Nature Nanotechnology. Still, scientists worrying about negative potential are a minority among their peers.

The report was based on a national telephone survey of American households and a sampling of 363 leading U.S. nanotechnology scientists and engineers. It reveals that those with the most insight into nanotechnologies are unsure whether they might pose health and environmental problems.

"Scientists aren't saying there are problems," says the study's lead author Dietram Scheufele, a University of Wisconsin-Madison professor of life sciences communication and journalism. "They're saying, 'we don't know. The research hasn't been done.'"

The new findings are in stark contrast to controversies sparked by the advent of technologies of the past such as nuclear power and genetically modified foods, which scientists perceived as having lower risks than did the public.

At the root of the information disconnect, explains Scheufele, who conducted the survey with Elizabeth Corley at Arizona State University, is that nanotechnology is only now starting to emerge on the nation's policy agenda. "In the long run, this information disconnect could undermine public support for federal funding in certain areas of nanotechnology research," says Corley.

"Nanotechnology is starting to emerge on the policy agenda, but with the public, it's not on their radar," says Scheufele. "That's where we have the largest communication gap."

While scientists are generally optimistic about the potential benefits of nanotechnology, they expressed significantly more concern about pollution and new health problems related to the technology. Potential health problems were in fact the highest rated concern among scientists, Scheufele notes. Twenty percent of the scientists responding to the survey indicated a concern that new forms of nanotechnology pollution may emerge, while only 15 percent of the public thought that might be a problem. More than 30 percent of scientists expressed concern that human health may be at risk from the technology, while just 20 percent of the public held such fears.

Of more concern to the American public, according to the Nature Nanotechnology report, are a potential loss of privacy from tiny new surveillance devices and the loss of more U.S jobs. Those fears were less of a concern for scientists.

While scientists wonder about the health and environmental implications of the new technology, their ability to spark public conversation seems to be limited, Scheufele says. "Scientists tend to treat communication as an afterthought. They're often not working with social scientists, industry or interest groups to build a channel to the public," he says.

The good news for scientists, Scheufele explains, is that of all sources of nanotechnology information, they are the most trusted by the public.

"I think the public wants to know more. The applications are out there and that concern gap has to be addressed," Scheufele argues. "The climate for having that discourse is perfect. There is definitely a huge opportunity for scientists to communicate with a public who trusts them."

Posted by

P. M. Earl

at

Monday, December 17, 2007

0

comments

![]()

Friday 7 December 2007

Code of Conduct for Responsible Nanotechnologies Research

7th December 2007

Following last week's IoN conference, the ENTA has posted the following response on its website:

Agenda

1. Nanotechnology has a huge potential with many benefits. Industry acknowledges concerns of potential risks of nanotechnology and any relevant regulatory regimes arising in the future could be welcomed provided they are rational, appropriate, take a balanced view of benefit VS risk and will assist industry to develop nanotechnology responsibly.

Industry is committed to building trust of the public through transparent engagement while assisting governments in delivering economic, social and environmental impacts as outlined in the scheme.

ENTA has a core value which states, “We must be responsible custodians of this exciting branch of science and ensure a fair framework that enables the EU to compete effectively on the world stage.” The Code of Conduct must not allow for the disproportionate application of the precautionary principle as in many applications, the Precautionary Principle may cause more harm than it alleviates.

2. ENTA welcomes this initiative as it encourages a responsible strategy and good governance of nanotechnology. However the safe development of nanotechnologies must provide scientific and sound data that meet policy objectives. Policy should not be driven by unsubstantiated risk concerns that have a high level of emotional appeal. Research would ideally be addressed by multidisciplinary teams. Against this background, what research is needed to allow the safe, sustainable and profitable development of the field of nanotechnology? ENTA recommends:

· More application driven funding for nanotechnology

· Less fragmented networks and more consolidation of efforts

· More training and communication activities

· Guidance on successfully implementing self-sustaining framework projects

There is also a desire to capitalise on FP6 and FP7 funding.

Also more clarity is desired regarding the “Open Forum” and term “use” of nanotechnologies should not be included in the Code of Conduct as the Code relates to research only.

3. ENTA welcomes the principles outlined by the Code of Conduct; however the final document should not include wording that implies the presumption of risk.

Many scientists agree that there was no special reason to suggest that products using nanotechnologies would be dangerous. ENTA members are working hard to provide consumers with safe products that are beneficial and meet societal needs and ENTA members ensure new nanotechnologies are developed in a safe and responsible manner.

The formation and implementation of a well-considered management strategy is critical.

4. Research should be conducted in all areas that lead to innovative products and devices which have the potential to greatly benefit society.

5. ENTA is happy to participate in follow-up measures and also participating in debates. The dialogue must be open, honest and continual and handled properly from the very earliest stages of nanotechnology commercialisation. Therefore it is vital for every company to clearly define and explain to stakeholders what is "nano" about their application, why it makes sense (benefits!) and how it relates to former technologies and solutions.

Sustainability, safety, and communication are also issues for SMEs and open debate about good H&S practices, information, communication, promotions and disclosure will become important issues for SMEs.

6. ENTA’s members would be balloted to determine this.

Posted by

P. M. Earl

at

Friday, December 07, 2007

0

comments

![]()

Investing in Medical Nanotechnologies II - Review

7th December 2007

Sponsors:

Mti

Marks&Clerk Solicitors

List of speakers

The Institute of Nanotechnology (IoN) held its second conference on investment in medical nanotechnologies at the Royal College of Surgeons, London.

The purpose of the two day event (28th-29th November) was to bring together companies, investors, entrepreneurs, authorities and medical professionals interested in the unique benefits (of) nanomedicine.

Among the following issues raised were:

Funding

Codes of conduct

The term Nanotechnology

In the Netherlands, concerns have been raised over foreign VC investment. Dr. Elaine Schutte (Signifix) spoke of the loss of investment when an idea/SME has received further (private) investment outside its own territory, e.g. the United States. The result can mean the eventual move of infrastructure. Currently, the Dutch governments’ grant funding is € 25 million.

Renzo Tomellini, Head of the Nanosciences and Nanotechnologies Unit (EU Commission) stated nearly €1.4billion in EU funding has been invested in more than 500 projects. He recognises the “financial gap between this (EU) and private funding.”

Pharmaceuticals

Professor Clive Washington’s (AstraZeneca, UK) talk included low strategies and early and late buying-in: “There are low strategies in nanotechnology within the pharmaceutical industry as opposed to other market segments. He stressed the importance of securing IP from the beginning, after “identifying the therapeutic target.”

When to buy-in?

Washington recommends shortening the average industry timeline of nine years (discovery, preclinical, etc) within the pharmaceutical industry in order to have a strong impact on drug delivery.

Early: quickly register IP; in-house resources; people, etc. The result, “IP can expire before product comes through.” Late: “low loss. Someone else’s shareholders have made the losses.”

Washington gave the following examples of new technologies: Bio Pharmaceutical and Advanced Drug Delivery. “The (Advanced Drug Delivery) industry currently has no well-defined formulation discovering” process.

This is the “gateway to attract funding.” Washington stated that “technical developments are done by start-ups and spin-offs.” And that “Critical Partnering” is crucial in helping to further develop a product. IP is hard to pin down for formulations and drug patents re: “nanosimilar products”; when they are structured the same as others.

What is the future of nanomedicine?

Working practices should enable the development of both molecules and formulation. In the past the industry has been accused of inflexibility however this is rapidly changing. Start-ups need to be supported, “getting sales people out there”, have the “marketing set up.”

Currently the range of products and services are diverse. It was said that some of these advancements have been around for up to ten years, but they have not reached the market. Time and again, many of the speakers stressed the importance of the outcome being the benefits to the patient.

There are neither specific regulations nor guidance in the pharmaceutical area re: nanoparticles. Robert Geertsma (RIVM) discussed the need for a new classification rule for “free nanoparticles.” The UK has a volunteer scheme although he said “it’s not been successful.”

Geertsma suggested a Volunteer Reporting Scheme (VRS) and to develop a regulatory guidance. He hopes there will be one “especially as there are combination products; “safety with availability of innovation” when using nanotechnology.

At one point his talk became a heated debate between Geertsma himself and a member of the audience as to the different health impacts and risks of nano particles and the term nanotechnology itself. Geertsma thought it was important to talk about all the risks of nanoparticles, products and technology.

The audience member raised the importance of public perception and the term nanotechnology and how it is being used. He gave the example of nanomechanical instruments “which may not have nanoparticles. Things may be nano in size but not have been made using nanotechnology.” More people joined in the debate. One man said that enforcement of a (VRS) “must not and should not be enforced. “To help make it successful it must be explained to both volunteer and governance/guidance.“

He believes that “areas should have their own codes of conduct; standards would be constructive.” Another audience member mentioned the Nano Code and that he had three different versions of a questionnaire on his desk. Another audience member said the ENTA will be meeting on 5th December 2007 to discuss Nano Codes. Several attendees had all three questionnaires.

Tomellini spoke of differing codes of conduct; one for researchers and one for business. They are both in the advanced drafting stage. They are not legally binding. However, courts can “take them into account in grey areas”. “No one wants regulation” but rather to “spread the culture of responsibility.” Tomellini said that “DuPont are developing a code of conduct.”

Dr. Thomas Keller (GlaxoSmithKline) pointed out that “there are no standards given to date for the pluses and minuses to nanomaterials.” One of the issues he raised was the lack of ”joined up thinking” despite “lots of initiatives.” GSK “are working with institutions and wants to participate but they feel governments and institutions need to take the lead on this.”

Tomellini believes in an “integrated and responsible approach to nanotechnology in strategy, action plan and report.” It should be “policy guided and inclusive approach, not top-down.”

Keller said GSK recently shut down their nanotechnology department of 40 people. He said it was “not the time to create a nano department. “ Instead GSK will be outsourcing their nanomaterials by “partnering with the finest in the world.” Eleven steps are taken for nanomaterials and “these approaches need to be integrated across from discovery to development. “ Both Keller and Dr. Ogan Gurel (XRoads, LLC) believe matrix management is needed, by “bringing (together) people from different disciplines.”

Gurel said that nanotechnology “requires almost everything to happen at the same time.” It is an enabling technology. “Because of this it’s difficult to value it - it’s not one single thing.” It is a “platform technology.” Therefore, partnerships are important.

He referred to GSK’s outsourcing rather than having anything done in-house. “Chief Partnership Officer is an important role as well as innovation partnering “even at the supplier level.” Gurel believes that the “VC model is not suited for nanotechnology or nanomedicine.” He believes “philanthropic funding helps to prevent the innovation gap.

Good people cost and it is important to have “top-notch management. However, many of the nanomedicine products are “not market orientated as they’re not about making money.” He feels “a holding or large company can help to offer some management. “

One of the investors I spoke with said this was off putting and not what an investor wants to hear. This investor (who wishes to remain anonymous) thought the mix of investors, scientists and chemists was inappropriate as the messages were mixed.

Receiving further funding is vital to the success of medical nanotechnologies (and other areas of industry) within the UK and Europe. More than ever, a clear definition of nanotechnology is required. People using nanotechnology within their industry sectors must come to some agreement. At this point in time they all seem to be searching for guidance.

It is important that investment is found to further develop the discoveries and SMEs. They are the driving force behind so much in this field.

Business Analyst Dr. Nicola Bailey (Wellcome Trust) said the Trust gives away £350-400million per year, both UK and overseas . The Trust is “looking in a health care product that will make a difference but which is not necessarily elegant. The financial return as a charity is not the end result - it is the impact on health care.”

Bailey went on to describe what she calls “the valley of death” or the innovation gap when universities and SMEs “want to see further development however they are unable to receive further funding. Bailey said that an IP does not necessarily need to be in place but “there needs to be the freedom to operate and a plan.” As it is a charity, the IP would remain the property of the university or SME. The Wellcome Trust also funds companies. She stressed the importance of “internal due diligence -checking patents, etc. They have in-house lawyers.

Perhaps it would be wise to put differing opinions aside when there is a mixed audience. The purpose of the two day event was to attract investment not drive it away. It is clear the developments they have made thus far are important. (Many of which have the potential to be used in other areas of industry, not solely medicine.) It would be a loss to us all if further investment is not made. One important area is that of Cancer. This will be discussed at another time.

Many thanks to

Carrie Smith, Events Manager, IoN

and to the Royal College of Surgeons

Companies

Nottingham Nanotechnology and Nanoscience Centre

Posted by

P. M. Earl

at

Friday, December 07, 2007

0

comments

![]()

Monday 3 December 2007

MICROELECTRONICS: New EUR 6 billion nanoelectronics R&D programme

MEDEA+, a European-wide collaborative research programme centred on microelectronics and part of the EUREKA project, has announced that CATRENE (Cluster for Application and Technology Research in Europe) is to be the follow-on programme designed to take electronics into the nanoscale era. The new programme has two important novel features: the Lighthouse Project - which will address major socioeconomic needs such as transportation, healthcare, security, energy and entertainment - and a new structure that will focus on large application markets, identified in a roadmap of required technologies.

Posted by

P. M. Earl

at

Monday, December 03, 2007

0

comments

![]()

Monday 26 November 2007

A little risky business

Editor’s Note: NW's editor has been subscribing to The Economist for nearly ten years. The newspaper has written other pieces on nanotechnology. Some may require subscription, which this editor highly recommends.

The risk in nanotechnology

Nov 22nd 2007

From The Economist print edition (please use link to see chart and illustration by Bill Butcher)

The unusual properties of tiny particles contain huge promise. But nobody knows how safe they are. And too few people are trying to find out

WAVING a packet of carbon nanotubes accusingly at the assembled American politicians during a hearing last month in Congress, Andrew Maynard was determined to make a point. The nanotechnology expert at the Woodrow Wilson International Centre for Scholars in

Dr Maynard's theatrics were designed to draw attention to a growing concern about the safety of nanotechnology. The advice he had received was at best uncertain, and at worst breathtakingly negligent. For a start, describing carbon nanotubes as graphite was rather like describing a lump of coal as a diamond. Graphite is made of carbon, just like the nanotubes, although the tubes themselves are about 1m times smaller than the graphite that makes up the “lead” in a pencil. Carbon nanotubes may be perfectly safe, but then again, they may have asbestos-like properties. Nobody knows. Indeed, industry, regulators and governments know little about the general safety of all manner of materials that are made into fantastically small sizes.

This lack of knowledge is so great that research can paradoxically add to the problem. Vicki Colvin, a professor of chemistry at

In the past few years the number of consumer products claiming to use nanotechnology has dramatically grown—to almost 600 by one count. Patents are rapidly being filed (see chart 1). For a product to count as nanotechnology, it does not need to contain a tiny machine—though some seers imagine that as the field's ultimate aim. It is enough merely for some of the material to have been tinkered with at a small scale. Often that can involve grinding down a substance into particles that may be only a few nanometres big—a nanometre is a billionth of a metre—about 100,000th of the thickness of a sheet of paper. These particles can also be engineered into shapes that provide some functional property, like rigidity. The variety of shapes includes rings, shells, wires, beads, cages and plates. The particles and shapes can also be incorporated into other materials to bestow useful properties on them.

Some nanotechnology products are applied directly to the skin, as cosmetics and sunscreens. Titanium dioxide is commonly used as the white pigment in sunscreen. When it is ground into nanoparticles it can still block harmful ultraviolet radiation, but it allows visible light to pass straight though, which means modern sunscreens can appear completely transparent, while offering the same protection as the old white stuff.

Many products are now embedded with silver nanoparticles. At such small sizes, silver can have antimicrobial properties. Silver nanoparticles may come in handy wherever you want to kill germs—for instance, in things as diverse as children's dummies (comforters to Americans), teddy bears, washing machines, chopsticks and bed linen. Hence nanotechnology can be used in food production, most often as nanoparticles of silver in food-preparation equipment. The food industry is also trying to restructure ingredients at the nanoscale so as to include particles of trace metals in food supplements and to produce less-fattening foods.

All that sounds alarming, but assessing the risks calls for perspective. Humans are already surrounded by nanoparticles of one sort or another. Much of the food people eat is made of naturally occurring nanoscaled components. Each person breathes in at least 10m nanoparticles a minute. Most of them do no harm.

The trouble is that some—such as the particles from a diesel-engine exhaust—are known to cause serious health problems. Moreover, despite hundreds of years of experience in chemistry, it is not easy to predict how a substance will behave when it is made extremely small. That means, you cannot be sure how it will affect health.

Nanoparticulate versions of a material can act in novel ways—indeed, as with silver, that is what makes them so useful. When they are very, very small, materials, such as copper, that are soft can become hard. Materials, such as gold, that would not react to other substances become reactive. And when they have been shrunk, materials, such as carbon, that are perfectly safe might become unsafe. Plenty of research suggests that nanoparticles of harmless substances can become exceptionally dangerous.

One reason for this change is that a tiny thing has a large surface area relative to its mass. Atoms on the surface of a material are generally more reactive than those inside (which is why powders dissolve more quickly than solids do). Half of the atoms in a five-nanometre particle are on its surface, which can make it many times more toxic than expected by weight alone. Nanoparticles are small enough to be transported into the human body more easily and into the environment in new ways.

Research on animals suggests that nanoparticles can even evade some of the body's natural defence systems and accumulate in the brain, cells, blood and nerves. Studies show there is the potential for such materials to cause pulmonary inflammation; to move from the lungs to other organs; to have surprising biological toxicity; to move from within the skin to the lymphatic system; and possibly to move across cell membranes. Moreover, these effects vary when particles are engineered into different shapes. There is currently no way of knowing how each shape will behave, except by experiment.

Many governments take the view that, in terms of product-safety, nanotechnology changes nothing. The responsibility for managing EHS risk remains with companies themselves. Firms must make sure that the goods they produce are safe for consumers, that their workers are healthy and that their factories and products do not cause damage to the environment. On the whole, that is the right approach in a market economy, but the uncertainties make it hopelessly over-optimistic for nanoparticulates.

In the absence of any firm guidance from governments as to exactly what tests are needed to ensure a product is safe, businesses are devising their own. Michael Holman, an analyst with Lux Research, an emerging-technology consultancy based in

The analysts at Lux reckon that the applications that are likely to cause most (real and perceived) concern are those intended to go into or onto the body: cosmetics, food additives, pharmaceutical-delivery systems, novel therapeutics and textile coatings and treatments. But Lux says there is also a lot of uncertainty over what happens to these substances at the end of their lives. Carbon nanotubes have been used for years in industry. They have been embedded in materials like plastics to increase their toughness and provide electrical conductivity for components that are electrostatically painted. But it remains unknown, for instance, if they can enter groundwater when the products that contain them are dumped or broken up.

Businesses have good reason to make safe products. But the temptation for a company, especially a small one, is to spend its precious research budget on new products rather than basic investigations into the safety of nanotechnology that would benefit everyone, including its competitors. The risks may end up being carried by insurers. However, Swiss Re, one of the biggest insurers and one that has taken an early interest in nanotechnology, reckons insurers are not yet fully able to assess the risks. At the moment, firms with product-liability insurance are implicitly insured for their nanoparticles.

One hope is that the insurers will demand more certainty. Another, given the fundamental principles that have still to be established, is that some of the money governments are pouring into nanotechnology (see chart 2) will be diverted into the basic safety research the technology needs to thrive.

Although scientists' favourite alarm call is that “more research is necessary”, the extent and the frequency of their cry suggests that in nanotechnology they may be right. The Nanotechnology Industries Association, a British trade body for companies operating in the field, wants better co-ordination in the way that money is spent on nanotechnology-risk research. According to Steffi Friedrichs, the association's director, “current research projects and their results are patchy to say the least.” Research tends to be in areas that interest scientists, rather than what would be most useful for industry as a whole let alone the protection of consumers. For several years there have been complaints about a lack of organisation and leadership.

Earlier this year the Council for Science and Technology, which advises the British government, warned that progress on risk research into the toxicology, health and environmental effects of nanomaterials was far slower than promised. It said there was a “pressing need” for a strategic programme of spending.

It is much the same story in

What are the most important things such a programme could produce? Dr Maynard says he would like to see ways of measuring exposure to nanoparticles in the air and water; a method of getting a rough idea of what the toxicity of a nanoparticle might be, ideally with some quick and basic tests that could inform scientists and businesses of the most promising (and safest) routes to pursue; and guidelines for how to work safely with nanoparticles, including clearing up spills and managing waste.

This does not sound like much to ask, but it is a long way from happening. In

This increases uncertainty over the safety of nanotechnology and makes the question of whether more regulation is needed a tricky one. Today's legislation is based on an ability to measure and monitor materials, and calculate risk. In

Terry Davies, a fellow at Resources for the Future, an economics think-tank based in

Managing the risks in nanotechnology is a massive undertaking that will take years to develop and it requires careful planning and co-ordination, says Dr Colvin. It will also depend on scientists from around the world working together. They could start by agreeing on a common form of terminology and some basic skills and tools, such as how to measure nanomaterials, characterise them and ensure their purity. At the moment it is virtually impossible to weigh a ten nanometre-sized particle with any accuracy. All this work is being co-ordinated via the International Standards Organisation in

Meanwhile, nanotechnology is becoming part of the global economy. It could help produce trillions of dollars of products by 2014, ranging from face creams to computer chips and car panels, according to Lux Research. The risks from these products will often be very low or non-existent. In the computer industry, for instance, making smaller and smaller features on the surface of a chip is not likely to involve much risk to computer users. Motorists probably have little to fear from carbon nanotubes being embedded into a car door to make it more crash-resistant. Yet what happens to such products at the end of their life remains a question.

At the same time, nobody wants to stifle the innovation and potential benefits that nanotechnology promises. Ultra-small particles that are able to enter the brain might be used to deliver treatments for brain diseases. Nanomaterials also offer huge potential for making better batteries, generating green energy and producing clean water. It is little wonder that governments have been falling over themselves to put money into nanotechnology research. Slower to arrive has been the leadership and funding to do the necessary risk research, and to make sure that existing agencies can regulate a large, new, poorly understood area of risk. Mihail Roco, a senior adviser at

Scientists do not mean that nanoparticles are inherently unsafe, only that there is a yawning gap in understanding their effects. Yet safety legislation cannot be expected to work until the products of the technology are better understood. What does it mean to regulate nanotechnology materials when you cannot even measure their release into the environment or agree on how to weigh a nanoparticle?

In the longer term, researchers think that they will be able to devise a framework for understanding nanoparticles and predicting which will be hazardous before they are ever made. That would allow science, technology and business to focus on the materials that are most likely to be beneficial and profitable. It would be a huge prize, because it would enable the development of nanotechnology while guarding against a big health scare or environmental disaster. If, in the aftermath of an accident, the public discovered that scientists are unsure about a wide range of nanotechnology, it would wreck the development of potentially valuable and safe new products.

Had Dr Maynard's bag split wide open in Congress, scattering his carbon nanotubes into the air, would any harm have been caused? Probably not. But, as an answer, “probably” is not good enough.

Posted by

P. M. Earl

at

Monday, November 26, 2007

0

comments

![]()

Tuesday 20 November 2007

Conference announcement: Nanotechnology: Towards Reducing Animal Testing

Animal testing is costly and there is a great deal of research on finding viable and effective alternatives (new methods that refine existing tests by minimizing animal distress, reducing animal usage, or replacing whole animal tests). Despite large reductions in animal testing since the early 1980s due to improved in vitro methods, levels remain high (over 3 million procedures in 2006) and results cannot always be extrapolated to humans.

The application of nanotechnology is currently revolutionizing medicine and this two-day conference, the first of its kind in Europe, will examine the role nanotechnology could also play in improving or refining the development of alternatives to animal testing whilst maintaining safety.

Themes will include:

· a review of some of the most promising human cell-based in vitro models

· novel lab-on-a-chip and bioreactor systems for screening, toxicology and targeting studies

· surface modification at the nanoscale to improve biosensors and in vitro test systems

· potential new strategies for applying nanotechnology to alternatives

· the role of the European Centre for the Validation of Alternative Methods (ECVAM)

The conference will be of particular interest to those involved in:

· pharmaceutical, medical device and cosmetic development and testing

· environmental and food testing

· regulation

· organizations interested in the development of animal alternatives.

For online registration and payment visit https://www.nano.org.uk/payments/index.php.

Further abstracts are welcomed for oral or poster presentations by 26 November 2007, please contact carrie.smith@nano.org.uk.

Standard Delegate - £500; Academic/IoN Member - £450;

Exhibitor (incl. one delegate) - £750; Additional delegate - £350

Visit www.nano.org.uk/events/ionevents.htm for regular updates on the event.

Fax to: 01786 447530 or contact Carrie Smith Tel: +44 (0)1786 447520

Registered charity no. SC 025709

Posted by

P. M. Earl

at

Tuesday, November 20, 2007

0

comments

![]()

Monday 19 November 2007

AMD, Carl Zeiss, and Qimonda partner on semiconductor nanoanalysis

Three companies -- AMD, Carl Zeiss SMT, and Qimonda -- are working together on new analytical and characterization methods required for the development of next-generation microchips. The work is being conducted within the framework of the Nanoanalysis Project, which the German Federal Ministry of Education and Research (BMBF) has backed with 12 million Euros. This strengthens the competency of the newly founded Carl Zeiss Innovation Center Dresden, particularly in the fields of semiconductor analysis and metrology.

Dr. Wolf-Dieter Lukas, Head of the BMBF Department "Key Technologies -- Research for Innovations," the strategic setup and expansion of microelectronics competency centers is an important goal. "Only by setting targeted priorities in research funding will we succeed in maintaining

The Carl Zeiss Innovation Center Dresden, an important part of the Nanoanalysis Project, offers ultrahigh resolution particle beam systems that use electron and ion beams instead of light. These systems enable the imaging, analysis and processing of specimens down to the level of individual atoms. In this way, they are playing a decisive role in the characterization of three-dimensional semiconductor structures and in the development of new materials for chip fabrication. "With its

"As a manufacturer of innovative microprocessors, we are faced with the challenge of producing increasingly complex structures with smaller and smaller dimensions and with maximum yield", says Dr. Udo Nothelfer, Vice President AMD Fab 36. "Therefore, process control at an atomic level plays a key role. Through our joint work in the Carl Zeiss Innovation Center Dresden, we have access to leading edge electron and ion microscopes and believe we can therefore further accelerate the introduction of new technologies. The experience gained in industrial utilization may be incorporated at an early stage in the development of future analytical systems."

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

Europe launches $8.8B (€6B) nanoelectronics R&D program

November 13, 2007 -- MEDEA+, a Europeanwide collaborative research program centred on microelectronics, and part of the EUREKA project, has announced that CATRENE (Cluster for Application and Technology Research in

The new program has two important novel features: the Lighthouse Project -- which will address major socioeconomic needs such as transportation, health care, security, energy and entertainment -- and a new structure that will focus on large application markets, identified in a roadmap of required technologies.

The MEDEA+ program supported 77 projects and the work resulted in important innovations within a number of areas, including automotive and traffic control, broadband communications, secure society, energy saving and health care. The new CATRENE public-private partnership aims to ensure the continued development of European expertise in semiconductor technology and applications.

Like MEDEA+ and its predecessors MEDEA and JESSI, the new program involves all the key actors in the value chain including those working with applications, technology and materials, as well as equipment suppliers. Industrial companies, both large and small, universities, and research institutes will take part with the support of public authorities.

"For more than a decade the EUREKA JESSI, MEDEA and MEDEA+ programs have made it possible for Europe's industry to reinforce its position in semiconductor process technology, manufacturing and applications to become a key supplier to markets such as telecommunications, consumer electronics and automotive electronics," said Jozef Cornu, MEDEA+ chairman and CATRENE chairman-elect.

The start date for CATRENE is scheduled for Jan. 1, 2008; it will last four years, extendable by another four years, and will operate under the auspices of the

Key technology goals contained within the program include maintaining and increasing

"Nanoelectronics will offer enormous opportunities to those who are the first to master and bring to market new technologies and applications and we believe that CATRENE will play a vital role in helping

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

Nanotech in food presents a regulatory challenge in Europe

The growing use of nanotechnology in food applications poses new challenges for both science and regulation in

EAS-Italy nutritional product regulatory affairs manager Stefanie Geiser said that as the nanotechnology market continues to grow, regulators and scientists are actively working to find regulatory and risk assessment models to embrace its research and safety aspects.

The first nano-food contact material (a silicon dioxide coating) has already been approved by the European Food Safety Authority (EFSA) this year, and a second, titanium nitride, is under review. However, EFSA has said that it will not be able to meet the European Commission's mandate for a complete generic risk assessment of nanotechnology by March 31, 2008 because of the vast range of existing nanomaterials with completely divergent physical/chemical properties and safety profiles.

Instead, EFSA has proposed to issue only an initial scientific opinion by summer 2008, and now plans to set up a working group of 10 to 15

A first discussion on this working strategy for nanotechnology will be held by the EFSA Scientific Committee November 19 - 20, 2007. Discussions will further be followed up at the Brussels EFSA Scientific Forum event November 20 - 21.

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

Nanotech Northern Europe 2008

23-25 September 2008, Bella Centre,

Nanotech Northern Europe brings together the field's top scientists and leading international companies in order to advance the beneficial use of nanotechnology. The 2008 event covers three application areas: Energy and Environment, ICT, and Nanobiotechnology and Nanomedicine. The conference will feature work ranging from the latest scientific breakthroughs to industrial uses of nanotechnology, whilst technology transfer sessions will offer opportunities for start-ups and universities to market their technologies. The exhibition will demonstrate developments in nanotechnology-based products, tools and other services.

For more information please visit www.nanotech.net

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

NanoTransfer 2007

December 3-4, 2007 • Novotel Charenton, Paris

Co-located with ENS 2007

Who will attend:

- Established companies interested in nanotechnology

- Nanotechnology Start-ups

- Investors and experts from areas supporting tech transfer

- Technology Transfer and Licensing Offices

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

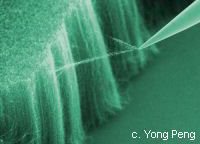

JPK translates BioSPM skills into sales success

James Tyrrell, editor of nanotechweb.org

JPK Instruments is one of

Torsten Jähnke, chief technology officer of JPK and one of the company's founders, knows the firm's products inside out. He spoke to nanotechweb.org about what it takes to develop an SPM for biological applications.

"It is important to introduce new technology into biology as a turnkey solution," Jähnke said. "Operators do not necessarily have a background in instrumentation, which you may find in physics or engineering."

Sample handling is another factor to consider. "The workflow can be completely different to other fields," explained Jähnke. "Biologists often take the same sample, mostly in liquid, from one tool to the next to build up a complete profile of the structure." Against this backdrop, the SPM has evolved to fit in with the whole analysis process.

"You must create a tool that can be combined with other tools – today's BioSPMs are increasingly integrated with other techniques, such as Raman spectroscopy and fluorescence microscopy," said Jähnke. "Users want to measure the chemical properties of their sample and to combine the data with SPM and optical images at the same spot and at the same time."

For a company like JPK this means partnering with leading research labs and attending not just SPM events but a wide range of related workshops in other disciplines, like fluorescence and confocal microscopy. In-house, the firm has put together a multi-skilled team to develop its instruments. "I think part of our success is due to the fact that at JPK, biologists sit in the same room as the engineers," commented Jähnke.

SPMs have come a long way since their inception. Closed-loop scanning stages have all but eliminated the problems related to piezo creep and hysteresis, but one of the biggest developments in recent years has been in the software.

"The user interface has improved tremendously," said Jähnke. "Researchers can calibrate or auto-align the system with one click." Software is now responsible for controlling the temperature and humidity of the sample and it plays a major role in guiding the user through the instrument.

"Operators don't want a six month learning period when they switch to a new instrument," explained Jähnke. "Today, technicians can get to grips with the equipment very quickly and that is due to the software."

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

The Kayli Prize Nominations

Sponsored by The Kavli Prize from the

Letters, the Norwegian Ministry of Education and Research, and the Kavli

Foundation

The Kavli Prize has officially opened its inaugural call for nominations.

Honouring scientists for their seminal advances in astrophysics, nanoscience

and neuroscience, each of three major international awards includes US $1

million, with the final selection of prize recipients to be made by the

remain open through December 15, 2007.

For more information, submissions, nominations and guidelines please visit:

http://www.kavliprize.no

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()

Nanotechnology cleans up fouling

James Tyrrell, editor of nanotechweb.org

nanotechweb.org caught up with Jim Callow, coordinator of the 31-partner consortium, at the University of Birmingham, UK, to find out some of the early success stories as AMBIO passes the halfway mark.

The situation today

Currently, biocide-containing paints are the mainstay of the industry. Applied to the hull of a ship, the coatings work well and tackle marine fouling by killing the offending organisms upon contact. The paints' constituents are permitted under the Biocidal Products Directive EC 98/8/CE, but there is restricted scope for innovation. The use of biocides is highly regulated, which makes it expensive to add new compounds to the list of allowed substances.

Biofouling experts, such as Jim Callow, believe that it is prudent for

In fact, a second technology, known as a fouling-release coating, already exists. The silicone-based treatment works by minimizing the adhesion between the fouling organisms and the hull of the ship. As the vessel moves through the water, the creatures are simply washed off. It's an appealing idea, but the method has its drawbacks. Ships need to be travelling regularly at speeds of between 12 and 15 knots for the coating to maintain a useful condition. The fragile nature of the silicone layer also poses another limitation, especially given the rigours of life at sea.

Nanostructured know-how

To preserve

"Bioadhesion is determined within a few nanometers of the surface," said Callow. "If you can understand what's going on at the adhesive interface then you have the means to control the fouling."

To solve the problem, AMBIO has brought together partners from a wide range of disciplines: marine biology, surface and interface science, hydrodynamics, polymer chemistry and engineering, microbiology, and nanotechnology.

"We are looking at the relationship between the chemistry and the mechanical properties of the surface," explained Callow. "And it's not just about paints, we are also studying other techniques, such as physical vapour or electrochemical deposition."

One approach involves the electrodeposition of silanes on roughened titanium. You can multiply the benefits by rolling different treatments into a single solution. If you get the surface chemistry correct then fewer organisms attach in the first place. Select the right amount of texturing and more of the fouling is removed.

"The idea that cells respond to texture is not new, but the exact influence of the nanostructures is unknown," said Callow. "We want to come up with a set of design rules."

There is certainly no shortage of concepts on the table. Potential antifouling solutions range from polymer blends that segregate to give a mosaic surface, through to the use of nanoparticles that moderate surface rugosity.

With many of the ideas as yet unpatented, Callow is careful not to give too much away. Ultimately, he thinks that around eight or nine approaches will emerge as contenders for scale-up and further development. The top performers will be selected for field trials that mark the final stage of the five-year project.

Tipped for success

One of the leading contenders is a silicone-based fouling release coating developed by the University of Mons-Hainaut together with Nanocyl, a maker of carbon nanotubes. Both of the partners are located in

"The coating is reinforced with carbon nanotubes, which also influence the surface topography," revealed Callow. "The challenge here is to get an even distribution of nanotubes in the silicone matrix."

Because the silicone has a tendency to wrap itself around the nanotube, the enhanced coating is much stronger and more robust than the original. Another benefit of adding carbon nanotubes is that the formulation becomes thixotropic, which gives the coating the characteristics of non-drip paint and makes it much easier to apply.

Making the grade

Conventionally, sample formulations are simply sent out to sea for testing. To speed up the process, AMBIO has come up with rapid adhesion assays for pre-selecting the strongest candidates. In one form of the test, the intrinsic properties of the new sample are captured by rastering a calibrated water jet over a glass slide that has been coated with the formulation and exposed to a test organism. The researchers can vary the shear force exerted by the jet to mimic the conditions at sea. Fluorescence measurements before and after reveal the success of the treatment in aiding the removal of creatures from the test surface.

Callow and his team have examined thousands of slides. Thanks to the rapid assay, the group has been able to narrow down the list of contenders from more than 80 to around 12.

Uncovering the secrets of fouling

Another innovation is the use of a holographic microscope. The apparatus works by reconstructing hundreds of sequential holograms to give an extended depth of field, which makes the technique ideal for observing samples under fluid. "It enables us to track individual particles in real-time as they approach the surface," explained Callow. "You can pick out the characteristic settling paths of individual cells that relate to fouling."

Plotted in 3D, the various swimming patterns are striking and offer a fouling signature that may prove invaluable in the development of new coatings. If researchers can come up with a structure that disrupts the organism's characteristic movements then it should make it much harder for spores to explore and ultimately foul the surface.

AMBIO facts

Number of partners: 31 (10 universities, 15 companies and 6 research institutes)

Start date: March 2005

Duration: 5 years

Funding: €11.9 million (EC) + €6 million (industry).

Posted by

P. M. Earl

at

Monday, November 19, 2007

0

comments

![]()