James Tyrrell, editor of nanotechweb.org

nanotechweb.org caught up with Jim Callow, coordinator of the 31-partner consortium, at the University of Birmingham, UK, to find out some of the early success stories as AMBIO passes the halfway mark.

The situation today

Currently, biocide-containing paints are the mainstay of the industry. Applied to the hull of a ship, the coatings work well and tackle marine fouling by killing the offending organisms upon contact. The paints' constituents are permitted under the Biocidal Products Directive EC 98/8/CE, but there is restricted scope for innovation. The use of biocides is highly regulated, which makes it expensive to add new compounds to the list of allowed substances.

Biofouling experts, such as Jim Callow, believe that it is prudent for

In fact, a second technology, known as a fouling-release coating, already exists. The silicone-based treatment works by minimizing the adhesion between the fouling organisms and the hull of the ship. As the vessel moves through the water, the creatures are simply washed off. It's an appealing idea, but the method has its drawbacks. Ships need to be travelling regularly at speeds of between 12 and 15 knots for the coating to maintain a useful condition. The fragile nature of the silicone layer also poses another limitation, especially given the rigours of life at sea.

Nanostructured know-how

To preserve

"Bioadhesion is determined within a few nanometers of the surface," said Callow. "If you can understand what's going on at the adhesive interface then you have the means to control the fouling."

To solve the problem, AMBIO has brought together partners from a wide range of disciplines: marine biology, surface and interface science, hydrodynamics, polymer chemistry and engineering, microbiology, and nanotechnology.

"We are looking at the relationship between the chemistry and the mechanical properties of the surface," explained Callow. "And it's not just about paints, we are also studying other techniques, such as physical vapour or electrochemical deposition."

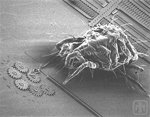

One approach involves the electrodeposition of silanes on roughened titanium. You can multiply the benefits by rolling different treatments into a single solution. If you get the surface chemistry correct then fewer organisms attach in the first place. Select the right amount of texturing and more of the fouling is removed.

"The idea that cells respond to texture is not new, but the exact influence of the nanostructures is unknown," said Callow. "We want to come up with a set of design rules."

There is certainly no shortage of concepts on the table. Potential antifouling solutions range from polymer blends that segregate to give a mosaic surface, through to the use of nanoparticles that moderate surface rugosity.

With many of the ideas as yet unpatented, Callow is careful not to give too much away. Ultimately, he thinks that around eight or nine approaches will emerge as contenders for scale-up and further development. The top performers will be selected for field trials that mark the final stage of the five-year project.

Tipped for success

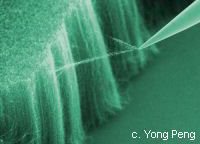

One of the leading contenders is a silicone-based fouling release coating developed by the University of Mons-Hainaut together with Nanocyl, a maker of carbon nanotubes. Both of the partners are located in

"The coating is reinforced with carbon nanotubes, which also influence the surface topography," revealed Callow. "The challenge here is to get an even distribution of nanotubes in the silicone matrix."

Because the silicone has a tendency to wrap itself around the nanotube, the enhanced coating is much stronger and more robust than the original. Another benefit of adding carbon nanotubes is that the formulation becomes thixotropic, which gives the coating the characteristics of non-drip paint and makes it much easier to apply.

Making the grade

Conventionally, sample formulations are simply sent out to sea for testing. To speed up the process, AMBIO has come up with rapid adhesion assays for pre-selecting the strongest candidates. In one form of the test, the intrinsic properties of the new sample are captured by rastering a calibrated water jet over a glass slide that has been coated with the formulation and exposed to a test organism. The researchers can vary the shear force exerted by the jet to mimic the conditions at sea. Fluorescence measurements before and after reveal the success of the treatment in aiding the removal of creatures from the test surface.

Callow and his team have examined thousands of slides. Thanks to the rapid assay, the group has been able to narrow down the list of contenders from more than 80 to around 12.

Uncovering the secrets of fouling

Another innovation is the use of a holographic microscope. The apparatus works by reconstructing hundreds of sequential holograms to give an extended depth of field, which makes the technique ideal for observing samples under fluid. "It enables us to track individual particles in real-time as they approach the surface," explained Callow. "You can pick out the characteristic settling paths of individual cells that relate to fouling."

Plotted in 3D, the various swimming patterns are striking and offer a fouling signature that may prove invaluable in the development of new coatings. If researchers can come up with a structure that disrupts the organism's characteristic movements then it should make it much harder for spores to explore and ultimately foul the surface.

AMBIO facts

Number of partners: 31 (10 universities, 15 companies and 6 research institutes)

Start date: March 2005

Duration: 5 years

Funding: €11.9 million (EC) + €6 million (industry).

No comments:

Post a Comment